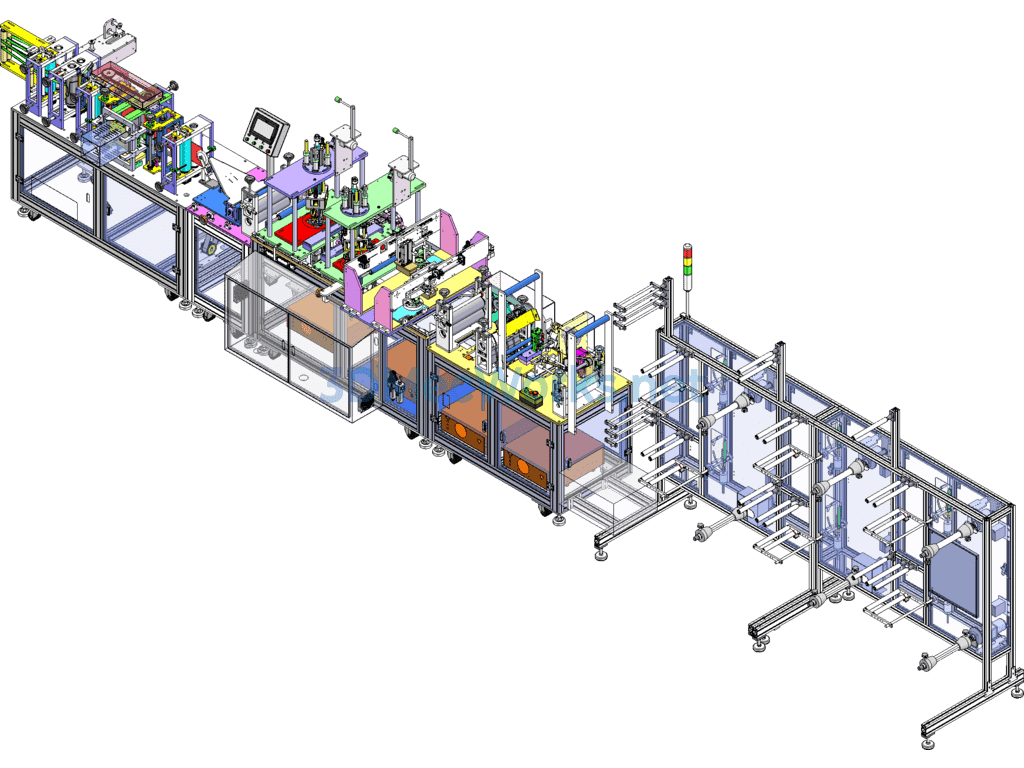

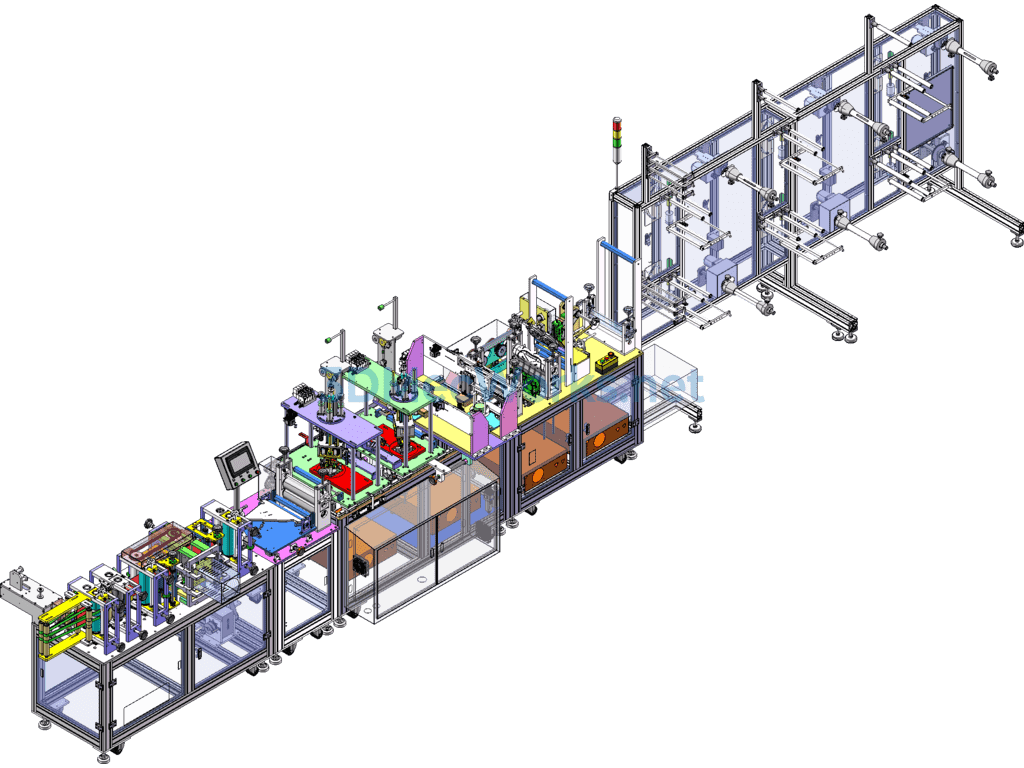

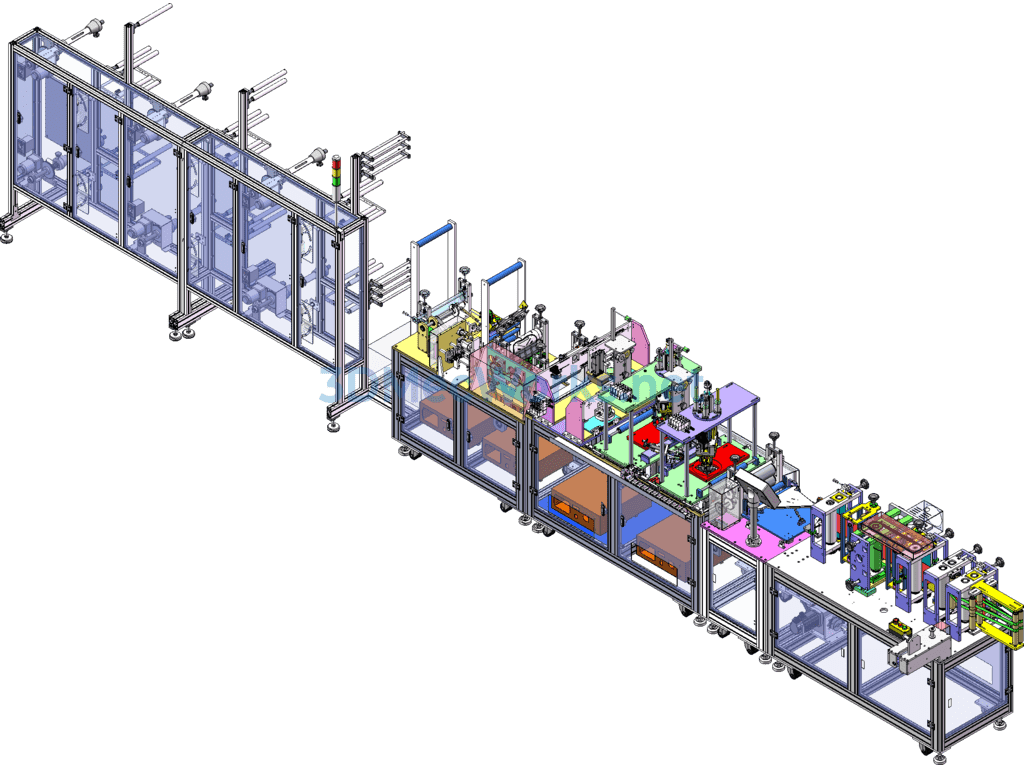

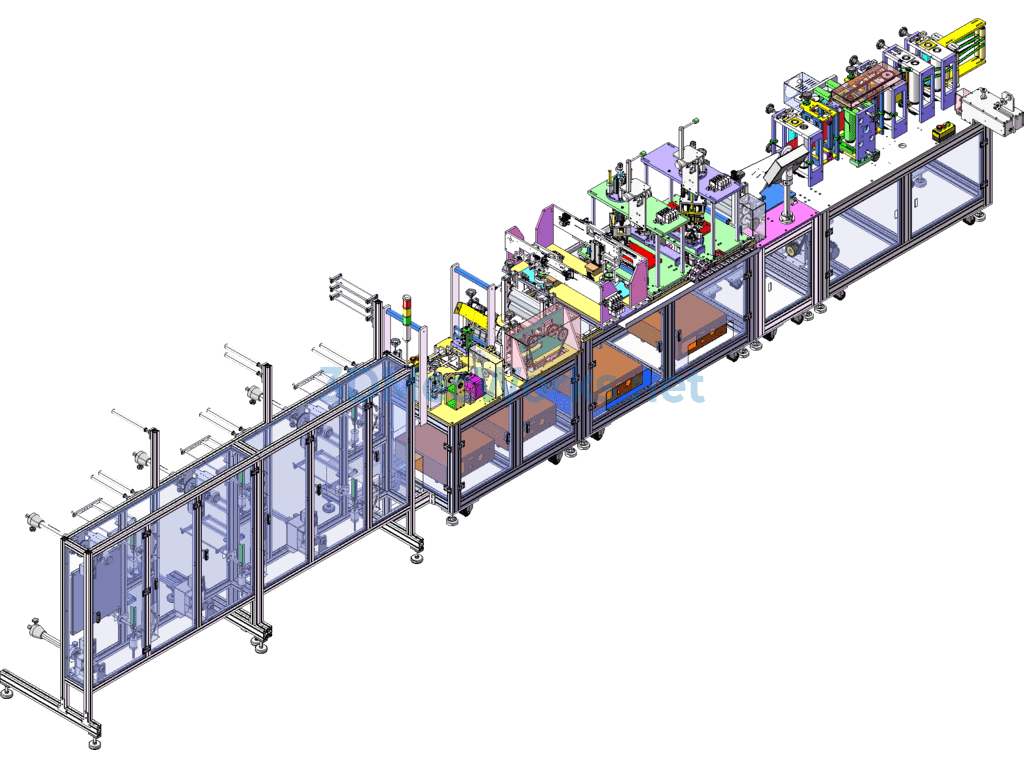

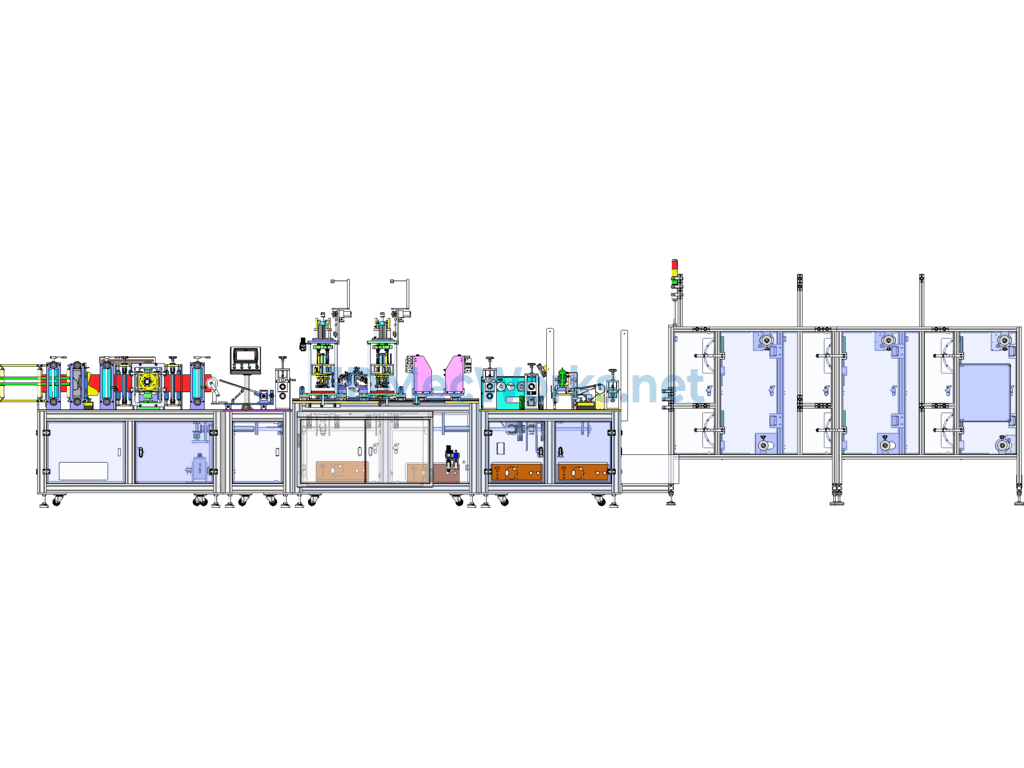

The production equipment of the N95 mask machine includes a complete set of assembly line equipment such as mask forming, mask edge pressing, mask cutting, earband welding, nose bridge strip installation, printing, and breathing valve welding. Among these, both mask forming and mask production use fully automated ultrasonic equipment. The mask’s edge pressing and cutting can be completed by a single machine, greatly improving production efficiency.

The N95 mask machine produces 40 masks per minute. The third-generation headband-style N95 folding mask machine uses adaptive cutting technology and ultrasonic automatic frequency tracking technology, significantly enhancing product stability and reliability.

There are no reviews yet.